Plug Flow Reactor (PFR)

Plug Flow Reactor (PFR)

Product

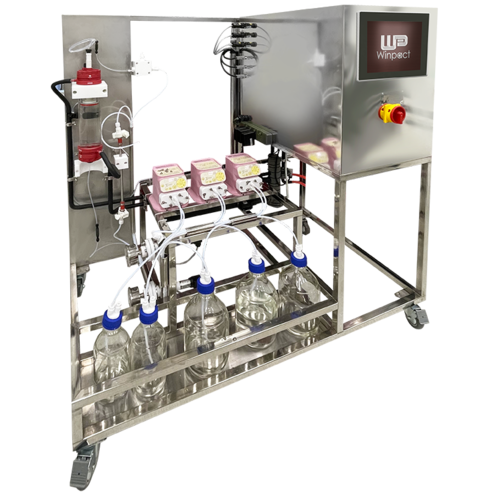

The key advantage of our PFR system lies in its high degree of modularity and customization, ensuring a perfect fit for your specific process requirements.

1. Ideal Plug Flow Reaction Environment

The system is based on the Plug Flow Reactor model design, guaranteeing precision and consistency throughout the reaction process.

Radial Homogeneity: Fluid properties (concentration, temperature) remain highly uniform across the reactor cross-section, providing reproducible reaction kinetic conditions.

2. Integrated Separation and Purification

The system is designed with the capability to integrate downstream processing, optimizing overall process efficiency.

Hollow Fiber Membrane Module: Can be optionally configured or integrated downstream for continuous re-filtration, separation, or concentration.

Enhanced Product Purity: Effectively separates particulates or impurities, simplifying subsequent product recovery and refining steps.

3. Human-Machine Interface (HMI) and Control Equipped with an intuitive Human-Machine Interface (HMI), allowing operators to easily monitor and set reaction parameters in real-time.

The system is based on the Plug Flow Reactor model design, guaranteeing precision and consistency throughout the reaction process.

Radial Homogeneity: Fluid properties (concentration, temperature) remain highly uniform across the reactor cross-section, providing reproducible reaction kinetic conditions.

2. Integrated Separation and Purification

The system is designed with the capability to integrate downstream processing, optimizing overall process efficiency.

Hollow Fiber Membrane Module: Can be optionally configured or integrated downstream for continuous re-filtration, separation, or concentration.

Enhanced Product Purity: Effectively separates particulates or impurities, simplifying subsequent product recovery and refining steps.

3. Human-Machine Interface (HMI) and Control Equipped with an intuitive Human-Machine Interface (HMI), allowing operators to easily monitor and set reaction parameters in real-time.

* All images are for reference only, actual products might differ from the pictures above.

* Technical specifications subject to change without notice.

| Category | Items |

|---|---|

| Reaction Unit | Customized design specifically tailored for Plug Flow Reactor requirements; reaction tanks (columns) can be designed to meet specific needs. |

| Feed Control | Precise feeding and pressure detection: Optional peristaltic, piston, or gear pumps for precise flow rate control. |

| Downstream Filtration | Integrated filtration system: Flexible configuration of Hollow Fiber modules. |

| Hardware Design | Flexible space and safety configuration: Mobile design with wheels for the entire unit, equipped with adjustable column clamps. |

| Control Interface | Intelligent HMI linked control: 12-inch touchscreen for centralized management of pumps, sensors, and monitoring points. |

| Data Security | Power-off data preservation: Features data backup functions in case of accidental shutdown or restart. |